Tea production technology

Tea production technology

The entire technical process of tea production is quite laborious, it goes through a series of stages, where each one has its own specifics.

Collection of raw materials - only the youngest upper leaves and green shoots are collected for this purpose. The most delicate and smallest leaves are more valuable than large ones.

Sorting of raw materials - careful sorting of freshly harvested leaves and shoots, removal of foreign debris, old and damaged leaves, rough stems. The most apical young shoots and buds (tips) are selected separately - they are used for expensive elite teas.

Already at this moment, the oxidation of the juice in the tea leaves begins and the basis of the taste and aroma of the tea is laid.

Important! Each batch of raw materials is accompanied by a separate certificate, which contains data on microbiological, radiological, physicochemical, organoleptic characteristics, the content of pesticides and heavy metal salts.

Withering - the leaves are prepared for subsequent processing, namely, drying and giving the leaf softness and elasticity under conditions of 20-25 ° C and 70% relative humidity, the process takes 18-20 hours.

It is done in two ways:

natural - leaves are laid out in an open area in the sun or in the shade. They are periodically shaken up for uniformity of the process;

in chambers with maintaining the desired temperature and humidity.

The first method requires large areas and special conditions, which are not always possible to provide. Usually the second method is chosen.

Here, the initial activation of enzymes takes place and chlorophyll is destroyed, which causes a sharp herbal smell. The achieved elasticity of the leaf ensures good curling and fermentation later on.

It is used for all types of tea, but depending on the variety, characteristics of raw materials and weather conditions, each manufacturer chooses its own special technology. For black varieties, this procedure is the basis for shaping the color, taste and aroma of tea. Green tea is wilted for a short time, from 2 hours, followed by heat treatment to stop fermentation. At the same time, the herbal bitterness leaves and the characteristic aroma of tea appears. For white teas, withering is the main step and there is no curling step.

Twisting - used for all types of teas, except for white, is carried out in two ways - manually or in rollers. Hand twisting is done in the production of luxury teas, it requires a certain skill. And on an industrial scale, drum rollers are used for this operation, in which the leaves are twisted under the action of rotation.

What twisting is needed for:

At this stage, preparation for fermentation and its activation are underway - rupture of cell membranes and release of cell juice, which reacts with oxygen.

The aroma is formed - essential oils are formed in the leaves, which give the tea the bouquet of aroma inherent in this tea.

This stage gives shape to tea leaves, in different varieties it is different - twisted along or across the leaf, flat, retaining the natural shape of the leaf, spherical.

Fermentation of tea - all teas pass this stage to varying degrees. But if black and red varieties need full fermentation, then green and white ones need only minimal fermentation. It is this stage that forms the characteristic properties of tea and its taste.

For fermentation of black tea, rolled leaves are laid out on racks or in cabinets in a room with good ventilation, high air humidity and a strictly set temperature - 22-26०С and even lower - for different varieties. To avoid direct sunlight, the fermentation room faces north.

During fermentation, the cell sap reacts with oxygen, as a result of this oxidation, substances are obtained that are responsible for the characteristic color and aroma of tea during its brewing.

The duration of fermentation depends on the season, weather conditions, leaf maturity, tea tree species, and previous processing steps. At lower temperatures and air humidity, if coarse raw materials are processed, the process is slower. Here, an “expert” (specially trained personnel is required) assessment of reaching the fermentation completion point, in which it is necessary to complete the process in time by high-temperature processing, is important. In general, fermentation lasts from 1 to 5 hours.

Drying - the final stage of processing, is carried out with hot air in two stages: first 90-95 ° C, then 82-87 ° C. At the same time, under the influence of high temperature, the fermentation is stopped and brought to the desired degree of humidity in order to maintain the achieved properties of the tea.

For this purpose, special bamboo dryers or drying chambers are used. Green teas are sun dried or roasted. Red teas in general undergo hot drying at all stages.

The drying stage prepares the tea for further packaging and storage. It is important to ensure the long shelf life of tea and requires compliance with all parameters.

Sorting and blending - the particles are brought to a homogeneous composition, the coarse ones are removed, the coarse ones are crushed to obtain the desired standard. The remaining tea chips are compressed into tiled tea. Shoot tops are used for high-end tea.

The resulting fractions of different types of tea are mixed (blended) in a certain ratio in mixers - blending drums, flavorings and herbal additives are added according to the recipe. Thus, the tea of the desired grade is brought to final readiness. A final quality assessment is carried out - tea tasting, after which it can be packaged.

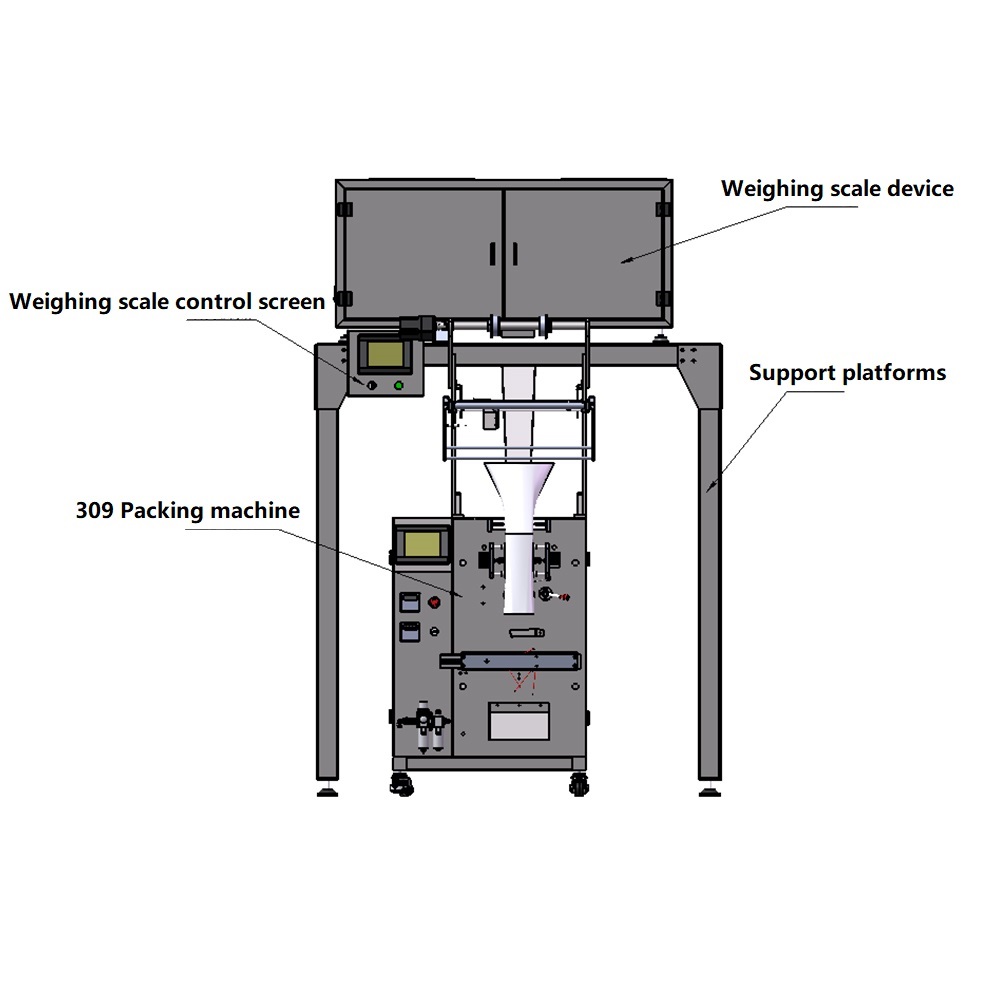

Packaging - packaging of ready-made tea in metallized packaging (soft and semi-rigid) weighing 25-250 g and more (1.5 kg). Tea bags are usually packed in filter bags of 2, 2.5, 3 and 4 g, 25 pieces per package.

Packaging allows you to preserve the properties of tea over a long shelf life. The tea in the package “falls asleep” until the moment of its brewing, when it, in all its splendor of aroma, “wakes up” in your cup.