Black Tea Manufacturing Requirements

Black Tea Manufacturing Requirements

Tea manufacturing requires an appropriate environment, infrastructure, and technique. The factories we visited on this field trip displayed strong production operations.

Below are five essential requirements for black tea manufacturing:

1.) Withering

Withering is the reduction of moisture content between 55/70 % to 75/80%, during which chemical changes occur in the tea leaves which are an essential part of the development of the flavor of tea. This process takes several hours, usually overnight and processing continues the following day. Withering must be maintained until completion, prior to the leaf being processed. Teas tasted on this trip evidenced correct withering. An efficient green leaf collection center within 3 km from the factory that inspects pre-final acceptance quality would cut down on unnecessary time in inspecting and rejecting substandard tea at the factory. It would speed up movement from delivery to the withering process. More detailed information about the proposed collection centers will be discussed below in the “Recommendations” section.

2.) Rolling

Rolling has two objectives a) to reduce the leaf size and b) to disrupt the leaf structure in order for the polyphones oxidize to be brought into contact with the flavones and facilitate efficient oxidation. The standard rollers, though getting old, were well maintained, and the function was carried out satisfactorily.

3.) Oxidation/Fermentation

Oxidation starts as soon as the leaf is disrupted. During oxidation the tea color changes from green to brown as the flavones and thearubigins form. Oxidation must be stopped when these have reached their optimum content and the tea quality has reached its peak. Throughout the processing phase, the leaves must be kept moist and their temperatures kept low to avoid unwanted substances being formed. An experienced tea-maker is required to manage this process because it is probably the most critical step in producing tea. Incorrect oxidation will spoil the tea and lead to disaster. I found the level of expertise in all factories visited to be of a high level, as evidenced by the teas tasted at each factory, including those receiving particularly bad leaf. Oxidation was carried out using the tray method or on a tiled floor, both methods were equally adequate.

4.) Drying

This operation stops oxidation at its optimum point and then reduces the moisture content of the tea to 2.5- 3.5% at which point the tea will keep its quality. The process is carried out by hot air which is heated indirectly by a heat exchanger from furnace-flue gasses. Fuel for the furnaces used in Nepal is a combination of wood and coal. Tea samples at the factory evidenced that dryers were functioning properly with no sign of smoky or burnt characteristics in the finished tea.

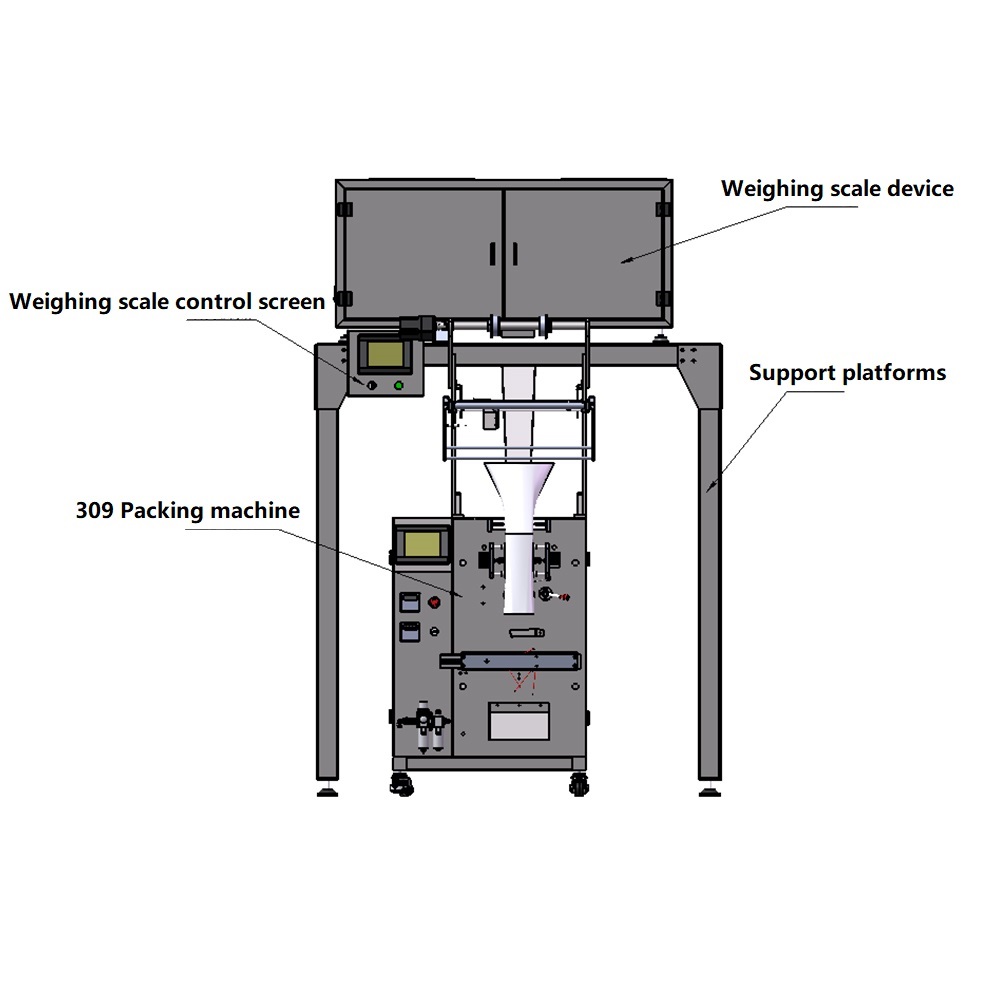

5.) Sorting/Grading

Tea from the dryer must be cleaned to remove any foreign matter, stalk and fiber, and then sorted into size ranges of established grades. This process is conducted over a series of sieves of various sizes and styles. This is a standard methodology used in Black Tea manufacturing in every tea producing country. The standard of cleanliness throughout the factories I visited was high, especially in the organic factories, where rules were strictly adhered to.