Description

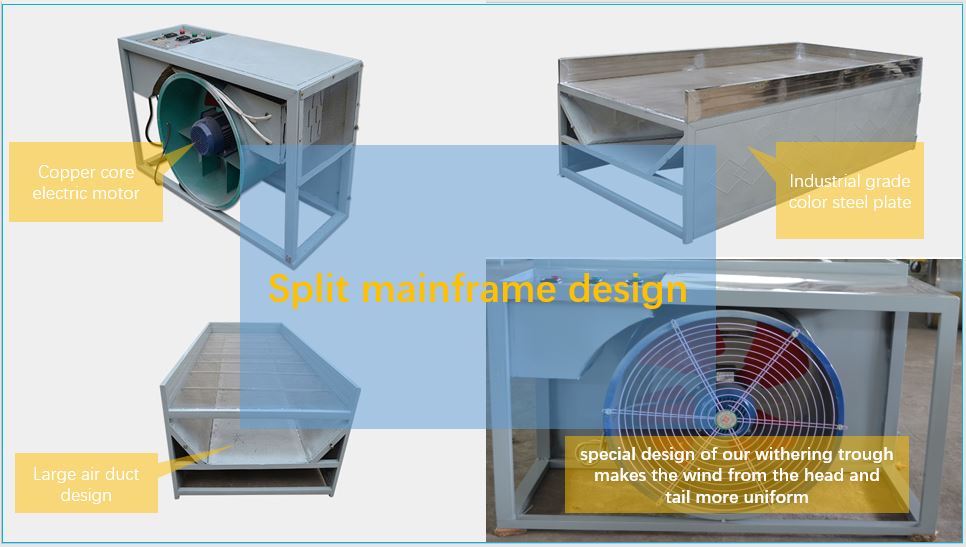

The tea withering machine consists of the frame, heat supply system and fans set and it is characterized that in the heat supply system a hot air duct is axially set in the cavity of the drum, the wall of the hot air duct is provided with air outlet holes, and the wall of the cavity of the said drum is provided with inclined stagger-distributed screw conveyance pieces and several axial distributed tea-turning plates.

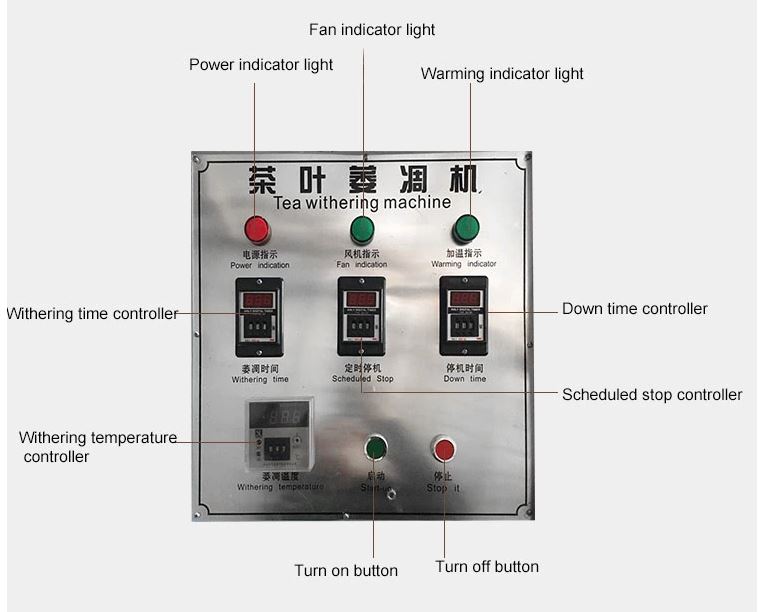

Intelligent microcomputer control system

The temperature of the blast is adjustable from normal temperature to 100℃ , which may fast remove moisture from the surface of fixed leaves, and prevents the withering and green tea kneading from weather impact. The primary processed tea has good and stable quality, and compared with traditional method, it saves great amount of machine, labors,materials and energy consumption.

Parameters |

Model | Outside dimensions | Integral power | Work | ||

Length | Width | Height | |||

YX-6CWD | 1200mm | 760mm | 600mm | 13kw | 380V |

Roles |

The collected green leaves are spread in a given thickness, and through air-drying they are under the withered state. During the withering process, the green leaves are subjected to a series of change: the moisture diminishes, the leaf becomes soft from brittle-hard to facilitate rolling and striping, the activity of the enzyme-containing substances increases, which promotes the decomposition and transformation of the green leaf ingredients (starch, protein and insoluble protopectin) to form effective substances advantageous to quality of finished tea (such as glucose, amino acid, and soluble protopectin), and somewhat oxidizes polyphenol-like substances.

Normal and effective withering will remove grass aroma from green leaves and generate delicate fragrance and fruit or flower flavor, and the finished tea is full of pure elegance but is not bitter. The withering requires proper temperature, RH and air circulation. The first process in making Chinese white tea, black tea and Oolong tea is withering at different degree. The withering degree of the white tea is the highest, and the water content in the green leaf shall be lowered to below 40% , that of the black tea is secondary and the water content in the green leaf shall be lowered to about 60%, and that of the oolong tea is the lowest, and the water content in the green leaf shall be lowered to 68%-70%.

About product installation, training and after-sales service |

Most products can be installed and trained through online video and text mode. If special products need to be installed on site, we will arrange technicians to install and debug on site.

Our Advantages |

Our factory is Anxi Yongxing Tea Machinery Co., Ltd.. It's a tea processing machinery enterprise integrated with design, manufacture and sale. The factory has more than 30 years of experience in producing tea equipment.

Reasonable prices and reliable quality. In tea processing industry, we have won the Innovation Achievements Gold Award of Employees from Both Sides of the Taiwan Straits, and Several National Patent Certificates.

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 SGS guidelines and our stringent quality control system.

Our Services |

1, We are professional on machine producing.

2, If have any questions during machine operation and delivery ,our sales manager and technical personnel will give you the best advice

3, If you want to know the machine operation please contact with us and we will send you video and detailed information.

4, If there is any questions, please do not hesitate to contact us in time and tell us what happened ,our technical personnel will give you the solution .

5, We will choose the most suitable machine with our professional knowledge.

Why us ? |

1.Quality guarantee

2.One-stop service without any outsourcing

3.Best Materials selection

4.On time delivery

5.Professional export for years